Introduction:

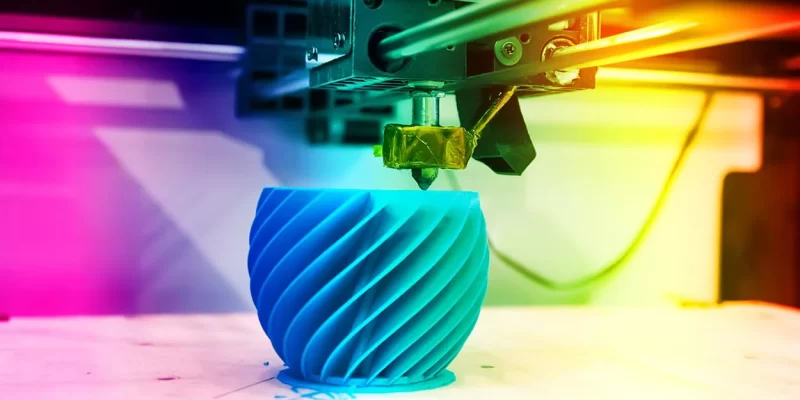

This technology has revolutionized the engineering, medicine, architecture, and manufacturing industries by allowing the creation of highly detailed and accurate models. But the accuracy relies on the 3D printing methods applied. Well, in this blog, we are going to take a look at the most accurate 3D printing services Vadodara that will help you make wonderful models.

Stereolithography (SLA) – High-Resolution Resin Printing

The printer works by using a laser to cure liquid resin one thin layer at a time,, creating very detailed and intricate models. SLA is commonly used in sectors that demand high precision, like dentistry, jewelry, and prototyping.

How It Works

- A vat of liquid photopolymer resin is cured with an ultraviolet (UV) laser.

- It then uses a laser to selectively add hardness to the areas defined by the model.

- The build platform lowers slightly, and new resin layers get cured.

- Once printed, the model is washed, cured under ultraviolet light, and, if desired, polished to give it a finer finish.

Key Advantages

- Exceptional Detail: SLA printers can produce layer resolutions as small as 25 microns, which is great for complex parts.

- Edge Smoothed: The end product has a high-quality finish, thus avoiding subsequent processing less.

- High Precision: Minor shrinkage rate and high-precision printing guarantee dimension accuracy.

Limitations

- Material Fragility: SLA resin components have brittleness and don’t fit functional parts that need durability.

- Additional Optimization Requires: Parts need to be washed, cured in UV, or sometimes sanded/coated.

Digital Light Processing (DLP) – Fast and Precise Resin Printing

Similar to SLA, Digital Light Processing (DLP) uses a digital light projector instead of a laser to cure the resin. 3D printing techniques increase the printing speed while staying highly accurate.

How It Works

- A vat of liquid photopolymer resin is exposed to a projected UV light pattern.

- DLP is faster than SLA because the entire layer of the model is cured simultaneously.

- The build platform descends, and the next layer is added and solidified.

- Steps that are executed post-print include washing, UV cure, and smooth.

Key Advantages

- Quicker Printing: Because DLP cures a complete layer at once, it prints faster than SLA.

- Fine feature detail: With features as fine as SLA, produce very detailed models.

- Good Surface Finish: DLP parts will not be quite as smooth as SLAbut will still have a finished look to them.

Limitations

- Build Size Limitation: Most DLP printers have small build areas, limiting the size of a model.

- Material Limitations: Like SLA, it is primarily resin-based, limiting functional use.

Selective Laser Sintering (SLS) – Strong and Functional Prototypes

SLS (Selective Laser Sintering) is another advanced type of 3D printing that fuses powdered materials (typically nylon or polyamide) by using a laser. As a result, durable, functional, and accurate models can be created even in high accuracy.

How It Works

- A layer of powdered material is placed onto the build platform.

- A laser selectively scans and spurs (sinter) the powder into a solid layer according to the design from its model.

- This process is repeated, with additional powder layers added and sintered.

- After printing, excess powder is removed, and the part is post-processed.

Key Advantages

- Heat Resistance: Resistance to warping and a high success rate for complex prints.

- Natural Support: Surrounding powder supports structure, accommodating complex geometries.

- Good Dimensional Accuracy: Parts are produced very accurately, allowing reproducible models.

Limitations

- Rough Surface Finish: Parts have a coarse texture and need post-processing to smoothen them up.

- Limited Color Availability: Most SLS models are monochrome and cannot be made aesthetically pleasing without painting them.

Multi Jet Fusion (MJF) – High-Performance Industrial Printing

3D printing services Vadodara build on SLS using a liquid fusing agent and infrared heating to develop very high-quality parts, strong but high resolution.

How It Works

- First, a fine layer of nylon powder is distributed on the print bed.

- A printer head lays down a fusing agent and a detailing agent that define the part’s edges.

- Infrared light mainly heats the fused segments and hardens them.

- The first layer is built and the process repeats until complete.

Key Advantages

- Great Accuracy and Detail: Achieves delicate details and sharp resolution.

- Greater Mechanical Performance: MJF components are tougher and more flexible than standard SLS prints.

Limitations

- High Cost: MJF printers are expensive, restricting accessibility.

- Rough surface finish: While better than those from SLS, parts may still require post-processing.

- Limited Material Variety: MJF currently primarily supports nylon-based powders.

Fused Deposition Modelling (FDM) – Cost-Effective and Versatile

The most common form of 3D printing is Fused Deposition Modelling (FDM), which is one of the cheaper and more versatile forms. 3D Printing Techniques operates by layer-by-layer extruding thermoplastic filaments to construct a model.

How It Works

- A hot nozzle deposits melted plastic on a build plate.

- The print head moves on the X, Y, and Z axes, layering material.

- Support removal and smoothing of the model might be necessary after printing is finished.

Key Advantages

- Affordable & Accessible: Great for hobbyists, educators & small businesses.

- Broad Range of Materials Supported: Works with a range of plastics such as PLA, ABS, PETG, and more.

Limitations

- Less Accurate: Less accuracy than SLA, DLP, or SLS, as you will have visible layer lines.

- Needs Supports for Overhangs: Complex geometries require adding structures for support.

Conclusion

The best 3D printing services in Vadodara depend on the application. SLA or DLP is perfect for ultra-high resolution. If budget is a concern, FDM is still the way to go. Designers, engineers, and manufacturers can explore these technologies to make the right choice for accuracy, strength, and efficiency of the 3D printing process. Also Read About Laser Mapping in Plants

Comments