Of all, trying to predict the global steel casting foundry future prospects is always a fruitless endeavor. However, this year would have generate more questions than it has answers. The effects of Europe’s ongoing discussion about the European Union’s future in a post-Brexit universe are uncertain, and the prospect of a new American president well instability in many other parts of the world all have an impact on how the markets will function and trade will be impact.

However, it is our responsibility to provide some direction and ideas on the topics discuss on the shop floors and in boardrooms of foundries and supply firms throughout the world, and we shall make an effort to do so.

The data use to create this material was collect from businesses and individuals working in foundries, supply firms, professional associations, research organization and academic institutions throughout the globe. There are a few conspicuous omissions, including Russia, about which little was known in advance of write.

The King Will Be Technology

Even when they are well-designed and maintained, foundries dangerous. Automation and cutting-edge equipment increasingly frequently used by metal casters and manufactures to reduce some of that risk and maintain a high level of competitiveness.

While ensuring a high level of accuracy and quality, automation solutions may significantly increase production and productivity. Furthermore, automation technology never gets worn out or burns out, with exception of human labourers, which may be avoided by creating preventative maintenance and care procedures.

Steel Will Continue Replace by Alternatives

However, lighter substitutes like aluminium are displacing the material due to its weight. Due to its strength and light weight, magnesium and zinc are also great options.

Especially in the automobile and aerospace sectors, but also in business and consumer electronics, we are witnessing this. Brass is a great example as well because of its exceptional conductivity and strong corrosion-resistance. steel casting foundry is becoming more common.

steel casting foundry Its smooth, readily changeable surface finish, great production potential, and improv dimension controls credit for this.

Industry 4.0 Has Arrived.

In a bigger drive toward Industry 4.0, the industrial sector has already adopted smart technology and implemented more digitalized operations. Information systems are use to drive and the adoption of smart sensors and link machinery.

Solutions utilising AI, big data, and machine learning will instantly evaluate vast amounts of incoming data to make judgments. To reflect market developments, they might modify their processes and equipment. In a moment, output may be ramped forwards or backwards to satisfy market demands.

Before a significant influence on the supply chain, defective or doubtful machinery fix or remove from the production line. Additionally, new and more sophisticate developmental and assembly techniques found and put into use at much quicker rates.

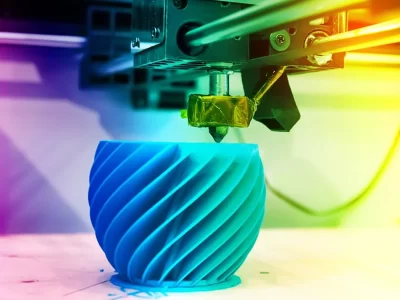

Manufacturing With Additives Is a Serious Business

it initially emerged, 3D printing, or manufacturing techniques as it is call in the business sector, was far more constrain than conventional techniques. That’s not the situation anymore. The method can work with a wide range of materials, including metal and valve casting manufacturers It is also producing components and goods that are bigger, more accurate, and of higher quality.

Commercial-grade metals is not an issue because the technology can print complete structures, such as a two-story administrative building. Additionally, additive printing makes it simple to create numerous objects that are intricate and challenging to build using traditional valve casting manufacturers techniques.

Also Read: Herbal Cranberry Capsule and Health Conditions

Conclusion :

Today’s globe is a completely different creature, and that many of the events taking place have an effect on the whole business sector, including metalworking activities. For instance, COVID-19 has hindered contemporary business and way of life.

A few of the trends influencing the direction of metal and valvecasting are automation, more effective materials, smart technologies, additive manufacturing, and environmental regulations.

The market is dynamic, therefore there will be many more trends in the future even if these are the ones that are currently most pertinent. For metal and die casting processes, flexibility is likely one of the most crucial criteria, if only to keep up with the times.

Comments